Products Description

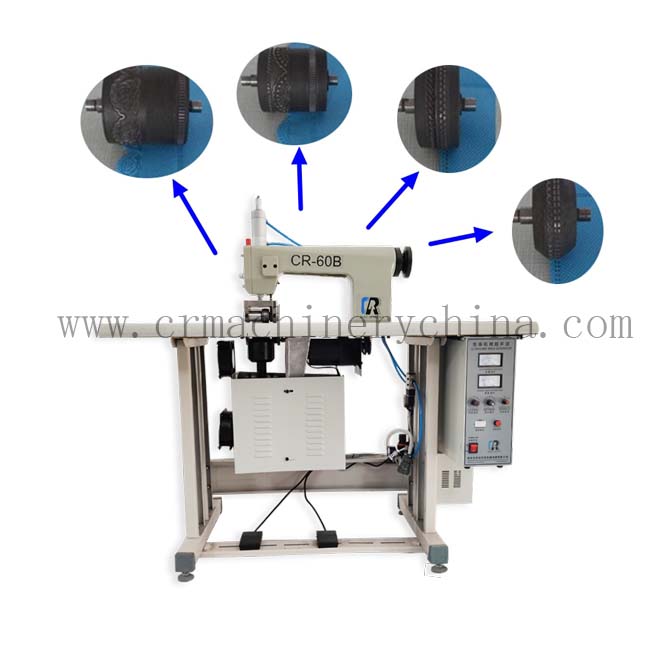

Function:

Trimming: Single-sided straight or curved cutting, and edge melting treatment, so that the edge is smooth, not rough, and without burrs;

Stitching: Two or more layers of fabrics are stitched together, wireless needleless instead of sewing, and good welding strength;

Hole-cutting: Cut out holes of various patterns, and do edge-melting treatment;

Stripping: Single or multiple strips of the material can be opened and cut at the same time, and the edges should be melted without burrs;

Forming: Cutting, stitching, and embossing at the same time, so that the product is formed at one time.

Features:

1. There are various patterns of flower patterns, and designs can be provided according to customer needs;

2. Super power output, with two levels of adjustable power, suitable for welding and cutting requirements of different materials and thicknesses;

3. Built-in computer chip and multi-channel ultrasonic protection system to ensure the safe and stable operation of the host;

4. The application of automatic frequency tracking system and ultrasonic soft start technology makes this machine powerful.

Application:

Suitable for ultrasonic lace sewing machine fabrics with synthetic composition over 65%, polyester, nylon, TC, sponge, non-woven fiber, satin, thermoplastic film. And other synthetic fiber materials. This machine is suitable for Lace clothing, synthetic filter bag, surgical gown, hair decoration, packaging satin, raincoat, tablecloth, chair cover, bedspread, pillowcase, quilt cover,handkerchief, Christmas ribbon, disposable operating coat, hook and ring. cut, pocket filter bag, non-woven bag making, shower curtain, etc.

Jane Xue

Jane Xue Jane Xue

Jane Xue